行業(yè)動態(tài)

產(chǎn)品

聯(lián)系嘉瑞杰

山東嘉瑞杰機械科技有限公司

聯(lián)系人:王經(jīng)理

電話:0531-88670722

手機 : 15866677695

地址:濟南市天橋區(qū)梓東大道鑫茂科技城143號樓102室

使用硅膠滑塊的低壓灌注模具的制作

來源:http://m.tescen.com作者:山東嘉瑞杰機械科技有限公司發(fā)布時間:2022-06-11

低壓灌注工藝及其模具的加工過程中,因為產(chǎn)品的結(jié)構(gòu)問題,會導致模具的加工中出現(xiàn)很多的倒扣位置。如采用傳統(tǒng)的類比注塑模具的鑲件及滑塊設(shè)計模具,則模具的生產(chǎn)難度和工作量很大,精確度要求很高,同時制作費用和生產(chǎn)周期很多,在小批量生產(chǎn)中造成成本過大的問題,甚很多結(jié)構(gòu)無法簡單通過一次成型加工,需要在模具成型后進行二次加工,步驟復雜。

In the process of low-pressure pouring process and mold processing, because of the product structure problems, there will be many reverse thread positions in the mold processing. For example, if the insert and slide block of the traditional analog injection mold are used to design the mold, the production difficulty and workload of the mold are very large, and the accuracy requirements are very high. At the same time, there are many production costs and production cycles, which cause the problem of excessive cost in small batch production. Even many structures cannot be simply processed by one-time molding, and they need to be processed again after the mold is formed. The steps are complex.

為了解決上述技術(shù)問題而提供一種能夠通過利用硅膠滑塊一次成型具有倒扣結(jié)構(gòu)的產(chǎn)品的使用硅膠滑塊的低壓灌注模具的制作方法。一種使用硅膠滑塊的低壓灌注模具的制作方法,包括:

In order to solve the above technical problems, the invention provides a manufacturing method of a low-pressure pouring mold using a silica gel slider, which can form a product with an inverted structure by using a silica gel slider at one time. A method for manufacturing a low-pressure pouring mold using a silica gel slider, comprising:

S1、繪制原件圖檔:選擇待生產(chǎn)產(chǎn)品進行該產(chǎn)品結(jié)構(gòu)的圖檔繪制;

S1. Drawing the original drawing file: select the product to be produced to draw the drawing file of the product structure;

S2、修訂模具原型圖檔:確定待生產(chǎn)產(chǎn)品的倒扣位置,并對S1中的圖檔進行修訂,在所述倒扣結(jié)構(gòu)外側(cè)包覆長方體塊,且所述長方體塊與所述倒扣結(jié)構(gòu)所處的待生產(chǎn)產(chǎn)品的表面貼合;

S2. Revise the mold prototype drawing file: determine the reverse position of the product to be produced, revise the drawing file in S1, wrap the rectangular block outside the reverse structure, and the rectangular block fits the surface of the product to be produced where the reverse structure is located;

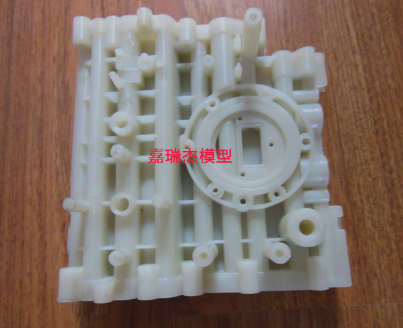

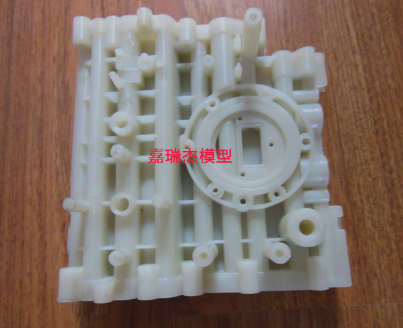

S3、制作低壓模具原型:根據(jù)S2內(nèi)修訂后的圖檔進行模具原型制作;

S3. Making low-pressure mold prototype: making mold prototype according to the revised drawings in S2;

S4、繪制倒扣結(jié)構(gòu)圖檔:將S2內(nèi)包覆的長方體塊繪制成單獨的圖檔;

S4. Draw the inverted buckle structure drawing file: draw the rectangular block covered in S2 into a separate drawing file;

S5、制作硅膠滑塊,根據(jù)S4內(nèi)繪制的圖檔采用硅膠原料進行硅膠滑塊制作;

S5. Make silica gel slide block, and use silica gel raw materials to make silica gel slide block according to the drawings drawn in S4;

S6、整體模具制作,將S5中制作好的所有硅膠滑塊按照S1的圖檔設(shè)置在S3中的模具原型內(nèi);

S6. Overall mold making: set all silicone sliders made in S5 in the mold prototype in S3 according to the drawing files of S1;

S7、低壓模具灌注,對S6內(nèi)制得的模具進行低壓灌注;

S7. Low pressure mold pouring: pour the mold made in S6 under low pressure;

S8、產(chǎn)品完成,取出S7內(nèi)灌注后制得的整體模具,制得含有所述硅膠滑塊的半產(chǎn)品,將所述硅膠滑塊拆除,并對半產(chǎn)品進行精修處理,得到成品。

S8. After the product is completed, take out the overall mold made after pouring in S7, make the semi-product containing the silicone slider, remove the silicone slider, and refine the semi-product to obtain the finished product.

優(yōu)選的,在S5中,所有所述硅膠滑塊均為左右開模結(jié)構(gòu)。

Preferably, in S5, all the silicone sliders are left and right mold opening structures.

優(yōu)選的,在S2中,所述倒扣結(jié)構(gòu)外側(cè)包覆正方體塊。

Preferably, in S2, the outside of the buckle structure is coated with a cube block.

優(yōu)選的,在S2中,所述長方體塊的尺寸均大于所述倒扣結(jié)構(gòu)的尺寸。

Preferably, in S2, the size of the cuboid block is larger than the size of the inverted structure.

其中,所述倒扣結(jié)構(gòu)為阻礙整體產(chǎn)品的開模方向的結(jié)構(gòu),即整體產(chǎn)品的開模方式為上下開模時,所述倒扣結(jié)構(gòu)的開模方式為左右開模或前后開模。

Wherein, the reverse structure is a structure that hinders the mold opening direction of the overall product, that is, when the mold opening mode of the overall product is upper and lower mold opening, the mold opening mode of the reverse structure is left and right mold opening or front and rear mold opening.

山東快速成型廠家認為這里的發(fā)明提供的使用硅膠滑塊的低壓灌注模具的制作方法,通過將待成型產(chǎn)品的倒扣結(jié)構(gòu)進行單獨成型支撐硅膠滑塊,并在制作原型時,將硅膠滑塊的尺寸置入原型內(nèi),使得在制作原型模具后,能夠?qū)⒐枘z滑塊直接放置在原型模具內(nèi),進行統(tǒng)一灌注,并在原型模具開模后,取下硅膠滑塊,得到成品。

Shandong rapid prototyping manufacturers believe that the manufacturing method of the low-pressure pouring mold using silica gel slider provided by the invention here supports the silica gel slider by forming the inverted structure of the product to be formed separately, and when making the prototype, the size of the silica gel slider is placed in the prototype, so that after making the prototype mold, the silica gel slider can be directly placed in the prototype mold for unified pouring, and after the prototype mold is opened, Remove the silicone slider to get the finished product.

以上就是今天所要講解的內(nèi)容了,相信大家在看完本文的描述之后,能夠?qū)υ摦a(chǎn)品有一定的認識和了解,希望以上內(nèi)容能幫助到你。另外,若你想要了解更多相關(guān)資訊,可以多多關(guān)注我們的網(wǎng)站動態(tài)m.tescen.com。

The above is the content to be explained today. I believe that after reading the description of this article, you can have a certain understanding of the product. I hope the above content can help you. In addition, if you want to learn more about our website, you can pay more attention to our website at www.jrjmockup com。

相關(guān)資訊

手板制作加工時注意事項

2024-04-11手板加工如何服務(wù)好客戶?

2024-04-09手板加工的過程及方式

2024-04-06快速成型的基本原理構(gòu)成有哪些?

2024-02-27工業(yè)產(chǎn)品設(shè)計中常見手板件的制作方式

2024-02-23ABS手板模型的優(yōu)勢有哪些?

2024-02-21鋁合金手板模型制作手法與維護

2024-02-10鋁合金手板模型的氧化工藝介紹

2024-02-10汽車手板模型制作的低壓灌注工藝

2024-02-06手把手教你怎么選機箱機柜定制工廠

2024-01-27